For more than half a century, Harbour Industries has powered aerospace innovation from Vermont.

Long before Beta Technologies put Vermont on the aerospace innovation map, Harbour Industries in Shelburne was already there–designing the cables that run through the world’s most advanced aircraft.

For nearly six decades, Harbour Industries has manufactured high-performance cables for commercial and military aircraft. In fact, chances are very good that if you’ve ever settled into your seat on a Boeing or Airbus flight and plugged in your headphones to stream a movie, it came to you through cables that were made in Vermont.

Precision Meets Innovation

A division of the Marmon Aerospace & Defense Group, owned by Berkshire Hathaway, Harbour currently employs just over 100 people in Shelburne. As data and streaming demands continue to grow, so will Harbour’s operations in the years ahead.

“The streaming speed ten years ago is nothing compared to what it is now,” says Charles Clement, president of Marmon Aerospace & Defense. “So the frequency is much higher, the energy required is much higher. You need video signal, audio signal and power–and you need it to be fast.”

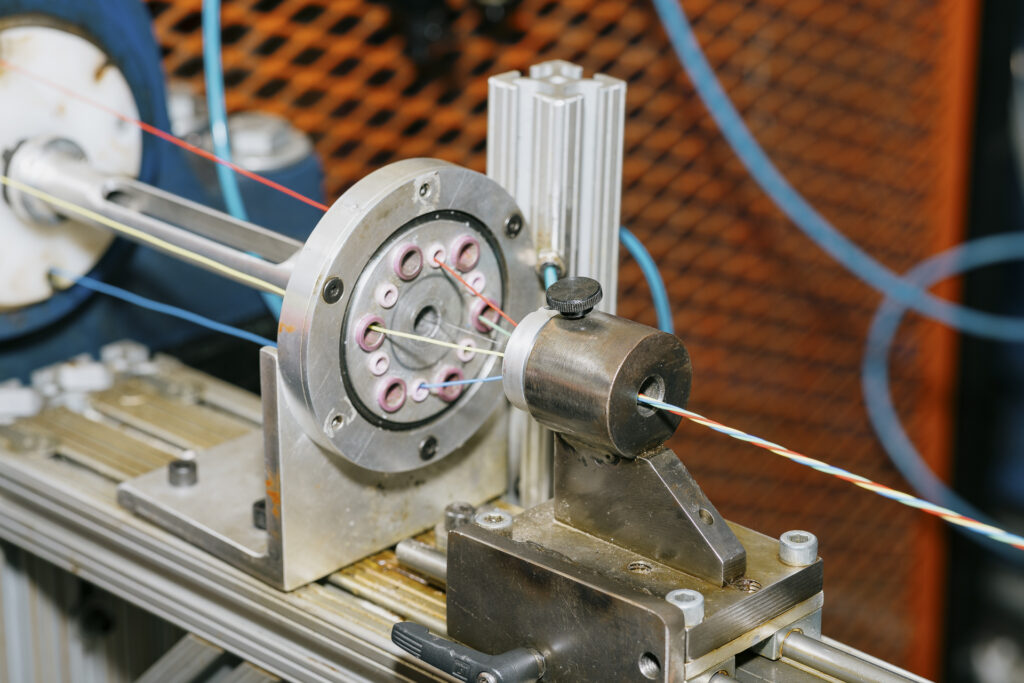

Harbour supplies cables to Distributors and Original Equipment Manufacturers (OEMs), the companies that design, build and assemble cable harnesses used in aircrafts. About half of the orders fulfilled by Harbour are made to military specification and follow proven protocols. The rest are custom designed cables. These highly-technical cables are used in everything from in-flight entertainment to navigation controls, and can contain 30 or 40 wires each with unique functions that have to perform flawlessly.

“The specialty side is where our engineers get creative,” explains Clement. “The applications are always changing. These are not cables you can buy in a store. They have to be lightweight, resistant to radiation and corrosion, and above all, nonflammable. The standards are much higher in aerospace because the risks are higher.”

Rethinking Recruitment

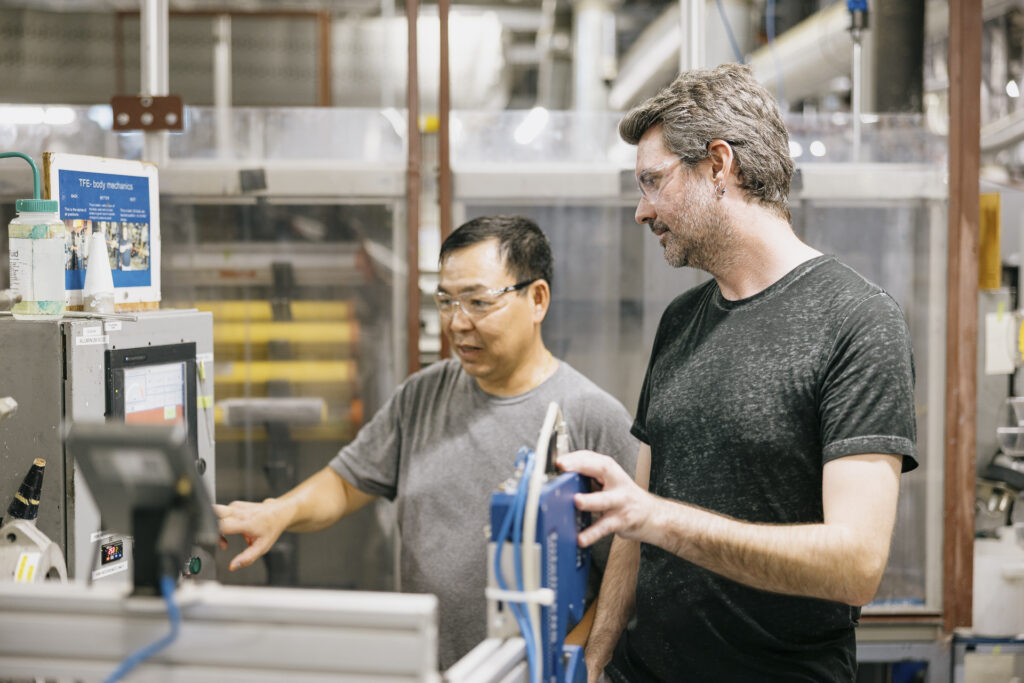

That’s where a skilled team sets Harbour apart. Many of the company’s employees have been with the company for decades. “Our materials are expensive,” says Clement, “so efficiency is important. The expertise on the floor means we’re problem-solving quickly with minimal waste.”

As part of a large corporation, Harbour is expected to grow annually. Clement sees that opportunity in developing new products. The company is currently in the qualification phase for a new cable design with a major OEM that, when approved, will require hiring approximately 40 employees at the Shelburne facility.

While that’s good news for the bottom line, Vermont is an expensive place to do business. Many of the company’s competitors have moved production to Mexico or China, but Clement believes the company’s skilled labor force makes up for the cost difference.

The challenge, he says, is finding labor. It’s a familiar refrain in Vermont, but Harbour approaches recruitment the same way it approaches manufacturing–with creativity and innovation.

Instead of posting job listings with a wish list of skills and attributes, Harbour reframed its approach around what they could offer employees. “We stopped saying we’re looking for this qualification or that,” says Clement, “and started asking, ‘Are you looking for stable income and great benefits? If so, manufacturing is for you. And, we’ll teach you everything you need to know.’”

The result? More qualified candidates than they can hire. “But we’re not slowing down,” says Clement. “People who have been here for decades are going to start retiring, and we need the new generation coming in and training under them. We need them transferring that knowledge.”

Making the Case for Vermont

With a new OEM on the horizon and job applicants at his door, Clement had one more problem to solve: timing.

“In two years, I will have the revenue,” says Clement, “but aerospace qualifications and manufacturing readiness take a long time. I need to start training people now.”

The company reached out to the Greater Burlington Industrial Corporation (GBIC), who helped Harbour secure a Vermont Employment Growth Incentive (VEGI) grant, a cash incentive designed to enable business expansion.

“It’s simple math,” says Clement. “Here’s the revenue I’ll add in two years, here’s the investment I need now. VEGI filled that gap for me and I could say to my boss, ‘Vermont is offering us this program, they are willing to help.’”

With that support, Clement has been able to bring on new employees to train with more senior operators.

“It works for everyone,” he says. “It allows people who are ready to retire to transition into a training role while the next generation gets up to speed, and it allows the company to grow and move forward. While we are a well-established entity and have a labor force that understands the product, GBIC and VEGI are positioning us for future growth in a tight, competitive labor market.”

For Clement, Harbour’s future in Vermont comes down to the same principles that have sustained it for nearly sixty years: skilled people and steady innovation. “The work we do reaches around the world,” he says, “but it all starts right here in Shelburne.”